If you’re a business leader running a mobile field operation, building a strong field safety program is a top priority. It’s also one of your biggest challenges.

Managing a large fleet of vehicles and assets along with a mobile workforce that’s on the road, dispersed across remote sites every day, adds layers of complexity to your role.

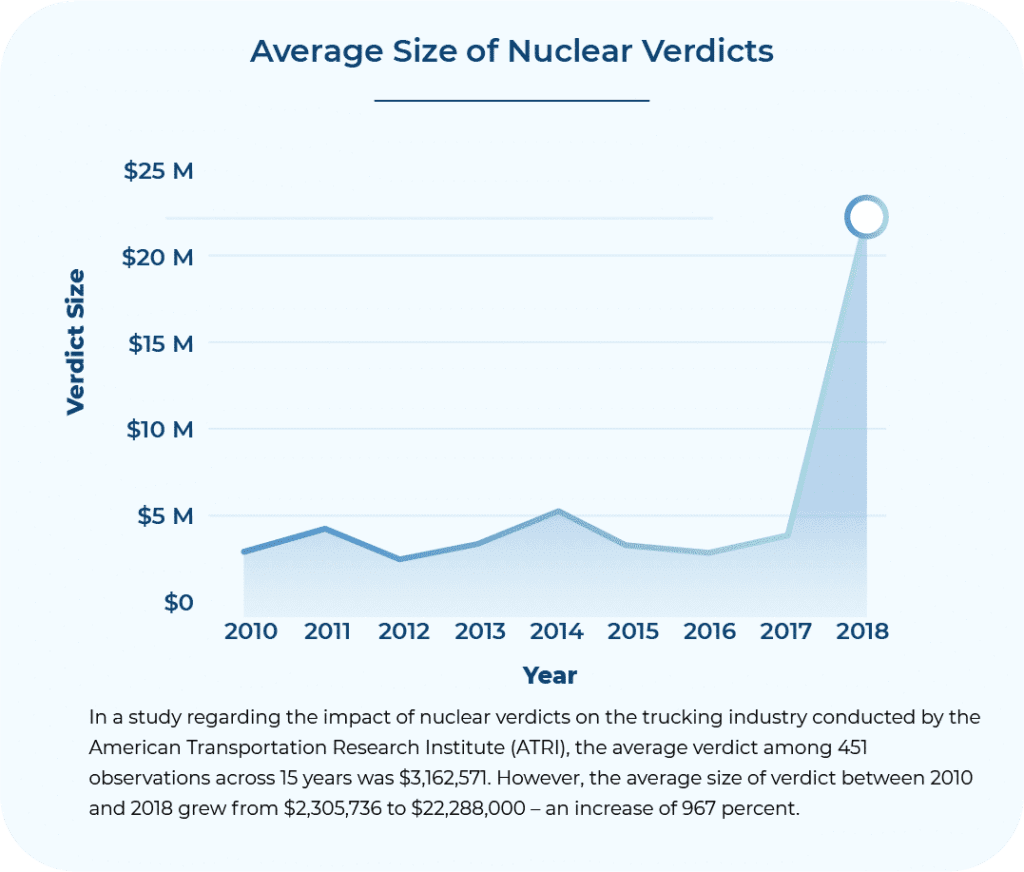

In a study on the impact of nuclear verdicts in the trucking industry conducted by the American Transportation Research Institute (ATRI), the average size of verdict between 2010 and 2018 grew from $2,305,736 to $22,288,000 – an increase of 967 percent.

These escalating verdicts highlight how a safe operation can determine business survival. It can also be a competitive advantage.

Rethinking Field Safety: From Cost Center to Profit Generating Edge

The most successful organizations no longer view safety as a cost center. They’re turning a holistic and proactive approach to safety into a competitive advantage that contributes to bottom-line profitability.

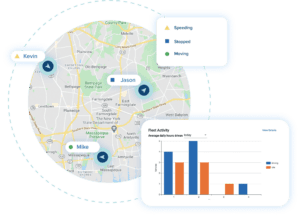

The key is end-to-end visibility – putting eyes on people, vehicles and assets at all times – with a strategically planned field safety program that integrates cross-organizational data to optimize business processes and workflows.

Why a Strategic Approach to Fleet Safety is Critical to Your Business Success

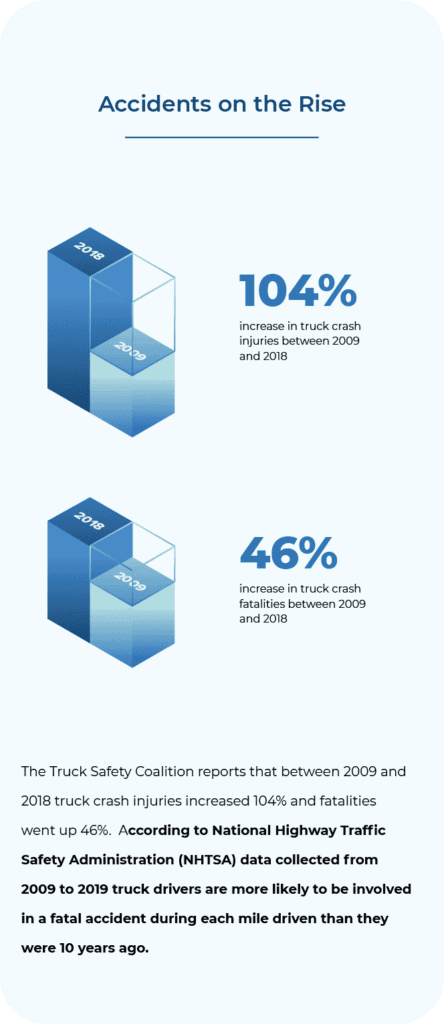

According to the Truck Safety Coalition, truck-crash injuries rose 104% and fatalities 46%, between 2009 – 2018. These statistics highlight the risk your drivers face every day.

They also illustrate the increasing vulnerability of fleet-driven businesses. Despite studies showing that as much as 80% of all truck-car crashes are caused by the car driver, commercial drivers are frequently and unfairly blamed.

False liability claims affect the driver’s record and open your business to escalating insurance premiums and unfair legal judgments – including the growing number of nuclear verdicts.

How Strategic Field Safety Programs Can Help Win New Business

Enhancing safety saves lives and cuts costs – and improved metrics give you a competitive advantage.

When you reduce safety and compliance violations, and the frequency and severity of accidents, your CSA (compliance, safety and accountability) score will improve over time.

CSA scores affect a driver’s record, and the fleet owner-operator reputation. A low score increases insurance premiums and leads to lost business when you’re seen as a high-risk operation. A solid CSA score, on the other hand, demonstrates a safe and efficient operation. That’s strong leverage for revenue generation.

Effective Safety Starts with an End-to-End Assessment of Your Current Program

To enhance your field safety program, first establish your baseline performance:

- Assess your policies, metrics and KPIs. Where are you hitting company safety goals? Where are you falling short? Pinpoint insight gaps that keep you from identifying improvement opportunities. For example, do you have full visibility into on-the-road driver behavior?

- Are your safety policies clear and fully communicated? Transparency in expectations, key metrics and corrective action resulting from violations will help your team continuously improve.

- Evaluate your internal training and coaching protocols. Is formal training supplemented with ongoing and in-the-moment coaching?

- Does your safety program encompass vehicle inspections and maintenance status to help prevent breakdowns that put your drivers at risk – and downtime that damages your customer experience?

- Measure the speed and responsiveness of reporting. Are paper-based processes and siloed data sets reducing your visibility and preventing quick action?

Baseline in hand, prioritize your next-step actions to expand visibility and move the needle on safety and profitability.

Leverage the Powerful Insight and Productivity That Comes with an All-in-One Solution

Choose a safety solution that offers all the tools you need in a consolidated all-in-one platform. You’ll cut the time managers and operators waste when switching between tools, simplify workflows and enhance security.

Plus, when you connect the dots between your data sets you get unparalleled business intelligence, enabling you to spot inefficiencies and risks, and continuously improve your metrics and processes.

Build Out the Key Components of an Integrated Field Safety Solution

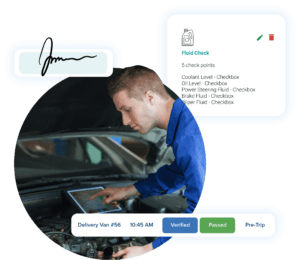

Optimize Your Inspections

Paper-based inspections are rife with risk – from delayed reporting, to lack of accountability for completing inspections. Small issues grow into compliance violations and breakdowns that put your operators in harm’s way and damage your customers’ experience.

Digital inspections eliminate these issues and give real-time insight to speed response time. You can quickly identify negative trends and recurring issues and give back time to your managers – cutting the manual data monitoring and manipulation to improve productivity.

Automate Maintenance Alerts and Status Reporting

Digital inspections also enable automated maintenance notifications. Unsafe vehicles are off the road faster and real-time reporting lets mechanics prep for repairs before a vehicle arrives, saving time and money.

Take it a step further and run a smart-servicing operation by integrating inspection alerts with your scheduled maintenance plans. Now, if a vehicle is brought in for a check engine light and is due for an oil change in two weeks, both services can be completed in one stop.

Leverage AI to Gain Full On-the-Road Visibility

This level of insight is arguably the most important component of operator safety – and protects against false claims, escalating insurance costs, and crippling legal payouts.

AI-enabled video cameras identify, alert and coach hard-to-detect risky and distracted behaviors to help prevent accident. If an accident or other safety event occurs, video and telematics data is automatically timestamped and available on demand.

The old he-said/she-said days of commercial drivers taking an unfair share of the blame are a thing of the past not that you have irrefutable video evidence to prove when your driver is not at fault.

Manage Operator Behavior with Scorecards

Coach drivers to success by monitoring and scoring critical driving behaviors like speeding, hard braking, aggressive turning, rapid acceleration, excessive idling and distracted behavior like phone use and lane departure.

And with integrated data sets, you’ll learn how behavior contributes to higher fuel spend, insurance and maintenance costs, and shorter than expected asset life.

Make your powered and non-powered assets visible and trackable 24/7

Don’t let equipment disappear from remote work sites – or be blind to unauthorized use of company vehicles. The ability to see real-time status as well as track the location to missing recover any assets is key to keeping your work sites productive and prevent costly losses.

Integrate Your Regulatory Compliance Data

Whether your operators fall under the ELD mandate to track hours of service, or they use a standard timecard, integrating that information with your safety data delivers important insights. You’ll see utilization by operator and fleet to optimize your worker productivity and ensure schedule compliance with hours-worked and breaks to keep your team safe.

Must-Have Requirements for an All-In-One Platform and Partner

Scales with your business needs. The most effective solution meets you where you are – in terms of fleet size and capabilities.

Offers full configurability. Ensure you can dial-in events and thresholds to monitor and report on your unique business processes and KPIs.

Enables easy integration. Gaining business advantage requires the ability to integrate siloed data sets to see safety data in the context of your broader operational processes and metrics.

Delivers rapid flexibility. Future proofing your organization takes speed, agility and flexibility. Insist on a solution that offers low code/no code configuration to keep pace with whatever comes your way.

Choose a partner in your success. The right platform and capabilities is table stakes. Choose a solution provider invested in your success. One with deep expertise and a customer-first partnership approach.

Ready to learn more about turning your fleet safety program into a competitive advantage? Request a demo.

![Episode 50 Thumbnail Erin celebrates building the fleet community with 50 episodes and 11K followers on LinkedIn [Podcast]](https://intellishift.com/wp-content/uploads/2021/08/Field-Safety-Post-Image-scaled-1.jpg)