Are you having difficulty getting visibility into key operational processes and fleet data that affect your day-to-day? Imagine having the ability to connect your entire field operation – a central hub that interprets reliable, real-time data and helps your whole team solve daily problems. Well, it is possible to connect telematics data, fuel usage data, fleet safety data, and maintenance and compliance reporting in one place. And it is the foundation of a truly efficient fleet operation.

What is Fleet Data?

Fleet data is the total collection of data points generated by connected fleet vehicles, assets, operators and back office systems. For example, field operations are likely collecting data from many of the following technologies at once:

- Vehicle telematics

- OEM telematics

- Fleet dash cams

- Daily vehicle inspections

- ELD logbooks

- Fleet maintenance systems

- Payroll and HR systems

- Fuel cards and usage data

- And so on…

Fleet data is used to improve processes, cut costs, increase uptime and improve conditions for their mobile workforce. But with so many technologies transmitting siloed data, it is difficult to sift through and connect it in meaningful ways. An abundance of fleet data doesn’t necessarily lead to quick solutions to fleet problems.

What Fleet Data Should You Track?

With so many data points to consider, it can be challenging to know the most important fleet data to track to improve efficiency. From obvious key performance indicators (KPIs) such as the number of incidents to less common KPIs like fuel consumption, we’ve put together the most important fleet data points to track.

- Predictive Safety Behavior: Tracking driver behavior helps you better understand the actions that frequently lead to incidents. Predicting these behaviors through telematics data and AI-powered dash cams can help prevent incidents from happening in the first place, improving fleet safety and lowering the number of incidents.

- Vehicle Performance: Vehicle telematics and GPS tracking solutions provide thousands of data points on performance and location. From harsh driving to diagnostic trouble codes, make sure you’re able to track everything happening with your vehicles and equipment.

Learn about Vehicle Telematics

- Fuel Usage and Purchase Trends: Fuel management involves monitoring speed, idle time, and routing. It also includes fuel card data, which can help you understand how efficiency is impacting purchase trends. When optimized, each of these elements helps decrease costs by cutting fuel consumption.

- Inspections and Maintenance: It’s important to monitor and standardize daily inspections and vehicle maintenance. Streamlining data from inspections can increase maintenance speed and uptime. Having historical maintenance data can help your team attribute driving trends and incidents to the cost of vehicle service.

Learn about Digital Inspections and Fleet Maintenance

- Hours of Service (HOS): To stay DOT compliant, you must track HOS through an electronic logging device (ELD). This will give you greater visibility into safety data, avoiding costly violations.

How to Connect Fleet Data For Greater Visibility

Total visibility is a challenge for fleet operations regardless of industry, especially larger organizations operating at scale. The most common challenge is bringing IT, safety and fleet operations to the table, with each function operating its own siloed technology stack.

IT: Teams are crying out for a single, secure solution that unifies their data, people, and processes. But IT has to manage upwards of 150 different technology solutions that don’t all work together, are redundant, and do little to promote fast data-driven insights. As you acquire new data every day, the ability to leverage the data becomes complex. For this reason, IT must evaluate siloed operational systems and connect the many sources of fleet data.

Safety: Safety is integral to company success. If a field operation isn’t employing safety technology, it puts their drivers, business and public at risk. Safety technologies like dash cams, ADAS and collision avoidance, and driver ID cards all contribute to the fleet data pool.

Fleet Operations: Fleet Managers need to be able to strategically determine how well their operations are running and be able to address day-to-day mishaps. And when issues arise, making decisions without real-time data can cause further inefficiencies and financial costs. Data comes in from telematics, GPS tracking, route management, field service and dispatch, fuel cards, compliance and maintenance systems.

Get the Guide: Learn how to connect your operations to make value-driven decisions for your company.

To connect fleet data, the function that manages your entire technology stack should work with your safety and fleet leaders. Together, they can list the entire fleet tech stack, identify redundancies, and evaluate the best tactics to combine and report on operational data. But what is the best way to do this?

A Modern Fleet Solution is the Answer

A modern fleet and safety platform will be able to unify the assets, data, people and processes within one screen. This helps companies gain a comprehensive view of health, profitability and productivity. Nothing makes an IT team happier than when your safety and fleet operations teams share one system of record.

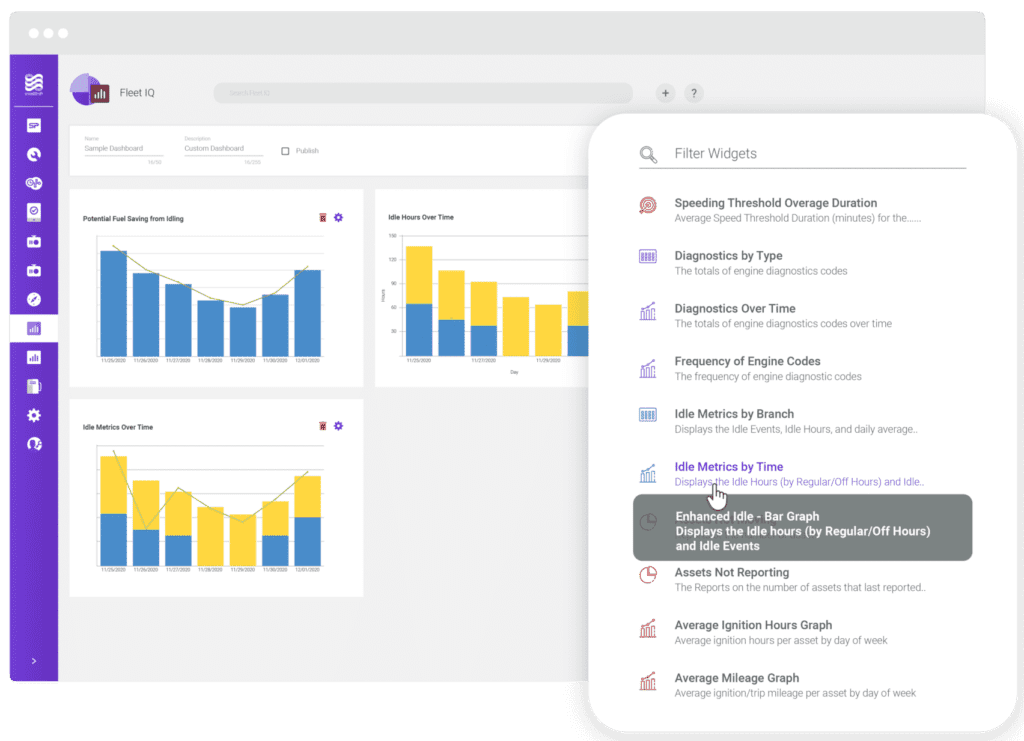

But a streamlined tech stack is not the only benefit of connected fleet and safety operations. When data is collected in one system, visualizing and combining fleet and safety data is much easier. A modern solution should offer multi-dimensional data visualization tools and dashboards configured to show you the data that is most important to your day to day. The result: business intelligence tailored to your operations and the ability to scale as your company grows and the industry advances.

With these deeper insights, your team will be able to quickly glean accurate and useful business intel without specialized program knowledge. This means you’ll be able to make more data-driven decisions, with the confidence afforded by a solution you can trust.

This is the baseline for a modern solution. The industry is changing rapidly and poised to grow tremendously over the next decade. For leaders looking to increase bottom-line value from their vehicles and assets, connecting operational data is no longer a nice-to-have. It’s a must.

The Future of Fleet Data

- AI video telematics is poised to become the norm with predictive analytics to increase driver safety and compliance.

- Artificial intelligence and machine learning are gaining greater adoption. This means faster, more reliable insights that learn and adapt as the business grows.

- Tools will become more natively integrated and easier to use. Users will likely no longer need to be as specialized to operate these solutions.

Fleet leaders looking for a modern solution must consider their future needs now. In an industry that’s expected to both grow and change rapidly, managers must choose a solution that’s built to scale, future-forward, and ready to handle and adapt to impending industry evolutions.

![Episode 50 Thumbnail Erin celebrates building the fleet community with 50 episodes and 11K followers on LinkedIn [Podcast]](https://intellishift.com/wp-content/uploads/2020/12/data-driven-operations.jpg)