A shocking number of commercial motor vehicle crashes continue occurring every year. In 2019 alone, 5,005 large trucks were involved in a fatal crash, a 2% increase from 2018 and a 43% increase since 2010. Yet many of these incidents could have been prevented by taking a proactive approach to fleet inspections.

Why fleet inspections are important

One of the most significant outcomes of fleet inspections is driver safety. The best way to ensure your employees will have a safe day is to proactively inspect the vehicle for dangerous defects. Inspections are also a first step in preventative maintenance, which helps decrease your fleet’s risk of breakdowns and reduces unnecessary downtime and repairs. By focusing on compliance, you can reduce driver liability and the likelihood of hefty fines. Fleet inspections can also increase the expected life span of your vehicles. Finally, regular inspections ensure that you are compliant with government regulations created and enforced by entities like the U.S. Department of Transportation (DOT), the Federal Motor Carrier Safety Administration (FMCSA) and the Occupational Safety and Health Administration (OSHA).

Types of fleet compliance regulations and inspections

Government agencies, including the DOT, FMCSA and OSHA, play a vital role in regulating fleet compliance. All U.S. commercial vehicle operators are subject to the DOT safety regulations. The DOT relies on its enforcement branch, FMCSA, to enforce compliance through roadside inspections. FMCSA officials look for threats that increase the risk of accidents. Then, that information is collected and fed back to the DOT to inform its regulations and crash-prevention programs.

As a fleet or compliance manager, it’s essential to understand the main areas of FMCSA’s fleet compliance regulations:

DOT & FMCSA Fleet Inspections:

Hours-of-service (HOS)

Because driver fatigue is one of the leading causes of commercial vehicle accidents, the DOT restricts the number of hours drivers can operate a vehicle without a break between shifts. The law requires drivers to electronically document their time using an FMCSA-approved electronic logging device (ELD).

Driver-vehicle inspection reports (DVIRs)

The FMCSA requires drivers to fill out DVIRs before and after every trip. Then, if your vehicle gets stopped by an agent, they will inspect the items on the DVIR checklist to confirm compliance.

Pre-employment screening and testing

You need to ensure that new and existing employees perform random drug and alcohol testing. Testing must be done during pre-employment checks and post-incident investigations.

Compliance, safety, and accountability (CSA)

The CSA score indicates how effectively you comply with FMCSA safety standards. Scores range from zero to 100, with zero being the safest and 100 being the worst possible performance.

OSHA Compliance Inspections

While the DOT and FMCSA regulate fleets on public roads and highways, OSHA oversees activity occurring on workplace property. This includes job sites, warehouses and other locations that involve the loading and unloading of cargo for business purposes.

OSHA has the authority to inspect any place of business. Many different things might trigger an inspection, but the goal is to ensure your business is compliant and taking proper precautions to keep your employees safe.

Some reasons why OSHA may initiate an inspection include:

- The presence of a hazardous scenario representing an imminent danger to employees.

- Following a severe injury that has taken place to an employee on-site.

- In response to employee complaints regarding health and safety hazards or violations.

- In response to other government agencies or organizations reporting a possible hazard at a worksite.

You can arm your site managers and safety staff to conduct regular, proactive OSHA self-inspection checklists to ensure that you’ll pass if and when an OSHA inspection occurs.

Traditional versus paperless fleet inspections

Many operators still fill in DVIR forms by hand, which has drawbacks. Besides the risk of being illegible, it’s also a very time-consuming process. Many fleets have issues with operators “pencil whipping” through an inspection form so that they can get on the road faster. And even when correctly completed, they are typically slow and do not provide any real proof. Manual inspections are typically handed over at the end of a shift or work week, meaning issues are often addressed well after the inspection occurred. Depending on how large your fleet is, you may find yourself with a mountain of paperwork that is difficult to track and can be easily misplaced.

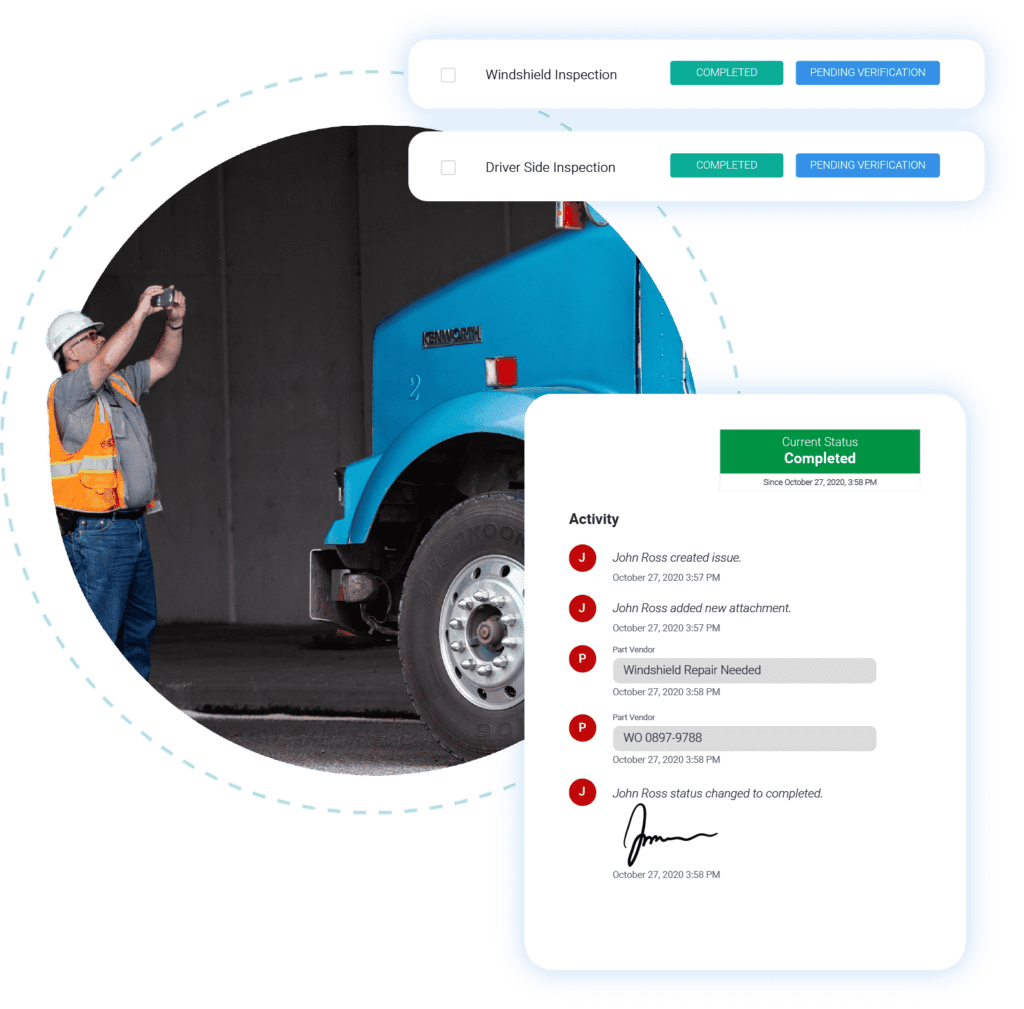

Fortunately, digital inspections can simplify the record-keeping process. Drivers perform vehicle inspections on mobile devices, sending data to a centralized dashboard accessible from any digital device. This means inspections are completed fast and accurately,

Benefits of paperless fleet inspections

Here are ten compelling reasons you need a digital inspection solution:

1. Saves Time

With digital fleet inspections, you can complete inspection reports more efficiently. That means your drivers can spend less time inputting data by hand and more time on critical items like maintenance.

2. Improves quality and accuracy of data

An electronic DVIR (eDVIR) allows drivers to take photographs of vehicle issues and upload them immediately for review. Now, managers have proof of inspection as well as details that would be difficult to communicate in writing. Digital forms also make it more difficult for drivers to pencil-whip through an inspection, increasing accuracy and accountability.

3. Reduces errors

Mobile apps and eDVIRs allow you to standardize inputs and form responses. Standardized responses are then stored digitally, available for review instantly. That way, you reduce the chance for human error and eliminate unnecessary paperwork.

4. Reduces costs

Over time, purchasing traditional inspection forms adds up. For example, assuming one logbook (which lasts a driver about a month) costs $4.95, you would need to budget at least $59,400 annually for a 1,000-truck fleet.

5. Improves workflows

Digital inspections allow you to set custom workflows, rules, checkpoints and proof-of-inspections requirements to ensure accuracy and visibility. You can also leverage automated alerts to notify operators and managers in real-time when an inspection fails.

6. More security

As a fleet manager, you may have to keep original DVIRs for months or years. The electronic approach minimizes the need for physical storage and the risk of lost or damaged forms.

7. More accessible

The paperless approach houses inspection information on a centralized platform immediately after a driver uploads it. That way, all relevant parties instantly have access to it. Anyone in the fleet has the ability to review inspection reporting at a high level and drilling down to specific branch, vehicle or driver.

8. Reduces impact on the environment

The transition from paper to digital saves trees, positively impacting the environment. In addition, it automatically reduces the number of pencils, pens and other items used—significantly reducing how much metal, rubber and plastic you use annually.

9. Configurable to unique inspection forms

You can tailor digital forms to fit any business process, including incident reporting and maintenance initiation. Configure templates with single or multi-point checklists to fit any daily inspection process, as well as local, state and federal compliance requirements.

10. Reduces downtime by connecting inspections to maintenance

With paperless fleet inspections, there is no lag in transferring information. Failed inspections send information to the service manager in near real-time to schedule repairs. Many digital inspection systems connect to existing fleet maintenance software, making it possible to initiate and track vehicle service from the point of inspection through to the shop.

Inspections should be an essential aspect of your safety, compliance and maintenance programs. But if you are relying on paper, chances are items are falling through the cracks. By getting ahead of problems using paperless fleet inspections, you will prevent unnecessary maintenance spending and better manage vehicle, asset, and equipment availability by preventing unexpected downtime and lost productivity.

![Episode 50 Thumbnail Erin celebrates building the fleet community with 50 episodes and 11K followers on LinkedIn [Podcast]](https://intellishift.com/wp-content/uploads/2021/12/iStock-1187421461.jpg)