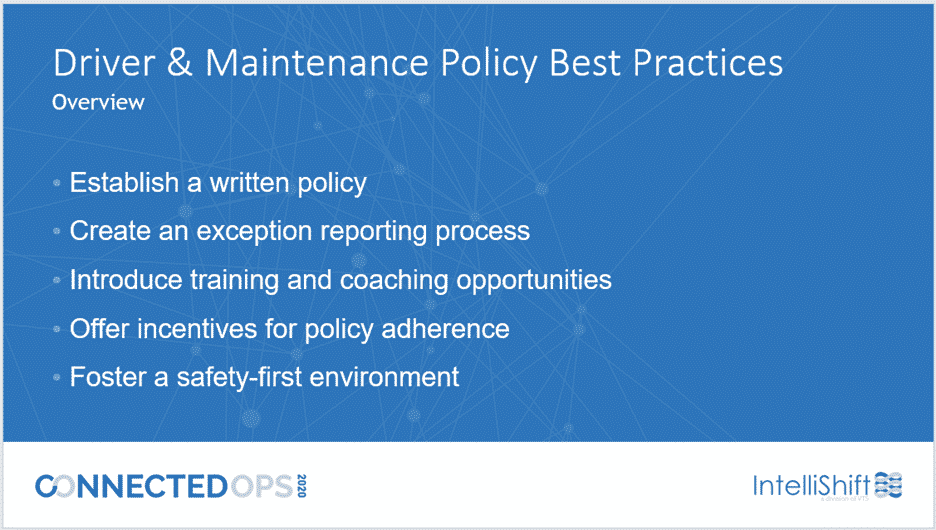

At IntelliShift’s ConnectedOps 2020 virtual conference, subject matter experts from around the company shared best practices in connected field and asset operations.

In his session, Best Practices in Fleet Maintenance and Safety, solutions expert Matt Aspinwall discussed how connecting your safety and maintenance programs will go far in assisting with building a safer and more efficient fleet.

In today’s environment, organizations face a variety of challenges in managing a large fleet. Maintaining adequate staffing levels, ensuring compliance with internal policies and external regulations, and minimizing maintenance downtime and expenses all have a significant impact on the business.

Missed ConnectedOps 2020? You can watch on demand

Drivers and mechanics are two key components in creating an operation that is safe, efficient and profitable. By establishing a clear set of best practices for both your drivers and your mechanics, you can set clear standards, reward good behavior and keep your team engaged.

Let’s start with a look at best practices for driver safety.

Establish a Written Driver Policy and Exception-Based Reporting Process to Drive Increased Safety

Driver safety starts with a written driver policy that is communicated throughout your organization. An effective policy outlines driver responsibilities and expectations, including:

- The strict observation of traffic laws

- A process and schedule for conducting inspections to ensure issues are identified, communicated to maintenance and addressed in a timely manner

- Personal versus company responsibility. For example, who is responsible for fines received while driving?

- Unacceptable behaviors such as texting or smoking while driving or driving under the influence

Equally important, is creating a separate exception-based reporting process that specifies how your organization will respond to incidents and violations when they occur – letting your drivers know exactly what to expect.

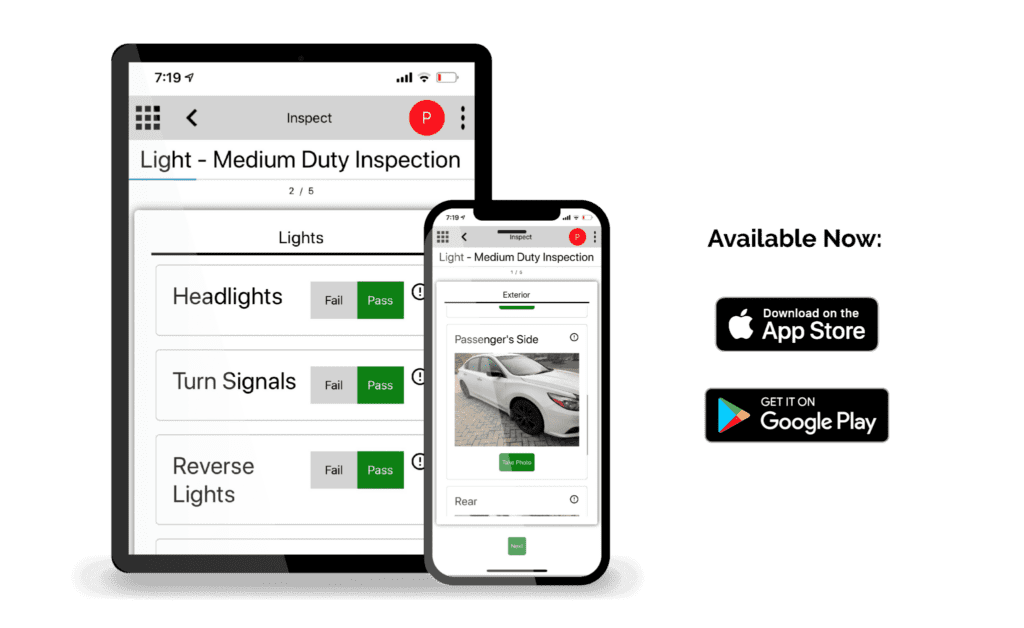

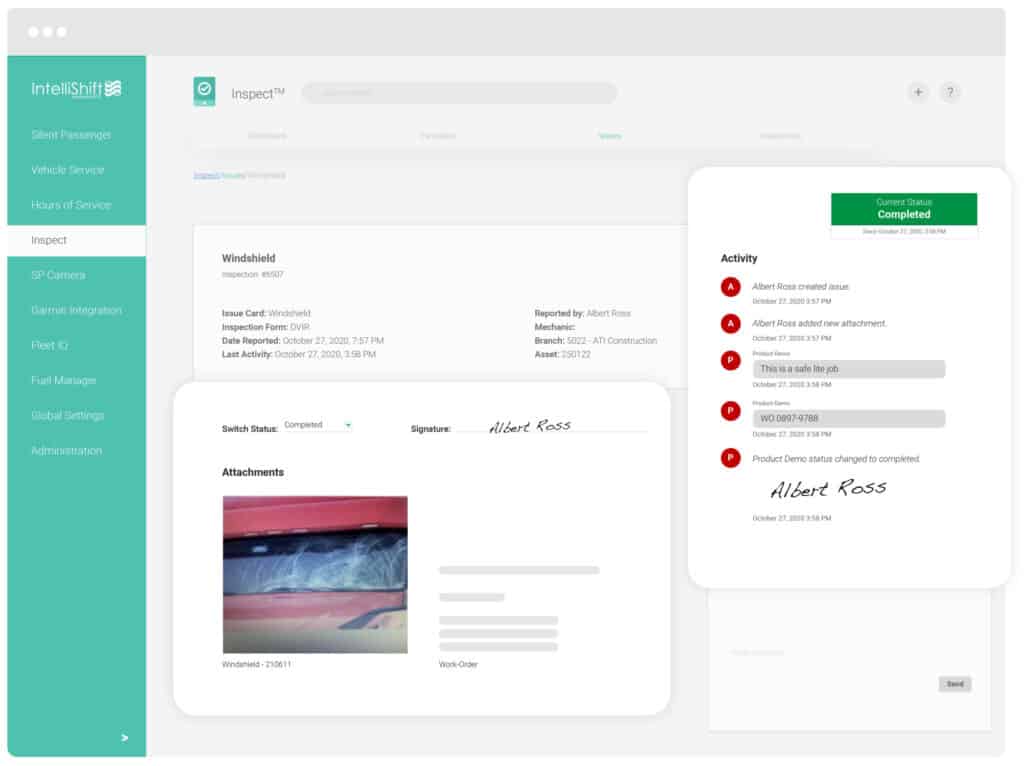

Using IntelliShift Inspect, for example, gives drivers a quick digital method for completing pre- and post-trip inspections as well as immediate incident reporting. Want added confidence that inspections are adhering to company policy? Require live photo capture from the Inspect mobile app.

A digitized log of incidents and exceptions also offers an opportunity for managers to review trends to identify any updates needed to your driver policy.

Leverage Training Programs and Coaching Opportunities to Increase Compliance and Engagement

For a policy to be effective, drivers must be fully trained – and the training doesn’t stop with the initial policy roll out, it requires a collaborative approach to ongoing coaching. Establish a driver scorecard that contains a clear set of metrics tailored to your company’s policies, and then ensure your drivers know exactly how their actions will impact their overall score.

When incidents do occur, approach them as coaching opportunities rather than personnel challenges – reinforcing the safety mindset. Use IntelliShift’s AI Video to gather even more insight – including 360-degree camera footage and event-based trigger information – to understand how the incident occurred. What can be done to minimize the risk of that incident occurring again in the future? Gathering feedback from the driver gives you the information needed drive future success, and to determine when policy adjustments will help minimize a negative driver behavior.

As with driver safety, establishing maintenance best practices begins with a clear written policy that covers expected actions from your mechanics.

Establish Maintenance Best Practices to Prevent Unnecessary Downtime and Minimize Costs

An effective maintenance policy includes:

- Preventative maintenance schedules based on manufacturer recommendations

- A schedule of preventative checks – in addition to the routine driver inspections – to catch issues not visible to the driver before they become a safety or costly downtime event

- Digitally documenting service activities – ensuring that all items are handled in a timely manner

- A procedure for measuring vehicle and asset lifespan – using information about preventative maintenance, number and type of incidents and driver behavior to spot trends that show how the different factors affect the average expected life

- A vehicle replacement plan. This could be based on the number of defects being reported, age or mileage. Planning for ‘sunset’ points will identify when the best course of action is replacement rather than repair

No matter how thorough your maintenance policy, collisions and maintenance exceptions are inevitable. Linking back to the driver policy exception reporting, IntelliShift Inspect can enable immediate reporting of incidents to your mechanics, allowing them to review the event – including description, photos, signature sign-off and diagnostic trouble codes – before the vehicle arrives on site. Tickets can also be issued to external mechanics, if needed.

Provide Ongoing Mechanic Training to Sharpen Skillsets and Keep Pace with Changes in Vehicle Technology

Keeping up with changes in the automotive space takes ongoing study. To keep your mechanics at the top of their game, provide the right materials and training support.

- Encourage training – either in-person training or online classes

- Provide easy access to vehicle manuals, technology references, industry magazines and newsletters

Incentivize Good Behavior to Increase Engagement and Retain Top Performers

Acknowledging and incentivizing good behavior contributes to increased policy engagement and to retaining your best drivers and mechanics. Effective incentives can range from company recognition – whether on a bulletin board, or through a group communication like a newsletter, or an employee-of-the-month award.

Other good incentives include:

- Celebrating major milestones like birthdays and work anniversaries

- Recognize instances of going above and beyond to get the job done efficiently and safely

- Offer safety and efficiency bonuses, or tangible rewards like plaques or company shirts

By visibly championing your best performers, you set a positive example for others to follow.

Ready to find out how IntelliShift’s connected operations solution can turn your best practice goals into operational reality? Let’s chat.

![Episode 50 Thumbnail Erin celebrates building the fleet community with 50 episodes and 11K followers on LinkedIn [Podcast]](https://intellishift.com/wp-content/uploads/2020/11/bigstock-Auto-Mechanic-Working-In-Garag-304454533-sm-scaled-1.jpg)