Vehicle downtime is an inevitable occurrence for any fleet.

Whether vehicles are involved in accidents, need part replacements and repairs as they age, or experience wear and tear from everyday driving, vehicle downtime is to be expected. While the cost of downtime can vary, it is important that you do everything you can as a fleet manager to ensure that your vehicles stay on the road as much as possible.

How much money does your business waste each time a vehicle is taken off the road for repairs?

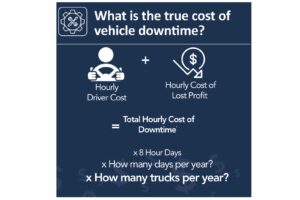

Vehicle Downtime Cost

There’s more to vehicle downtime costs than service, repairs, and part replacement expenses. In fact, when you take into account the amount of money you’ll still spend paying your drivers and the amount you’ll lose on missed jobs.

Here’s a look at the breakdown of spending on driver cost and lost profits:

Multiply that by the number of days of vehicle downtime, drivers, etc. and you’ll see just how much money you’re spending on downtime.

What if you could avoid that cost by implementing a vehicle maintenance program that reminded drivers to monitor vehicle health?

Unexpected vehicle downtime caused by mechanical issues or accidents can have serious effects on your fleet’s productivity. You could lose hours, days, or even weeks while a vehicle is being repaired or serviced and if you do not have extra vehicles one of your drivers is also losing work.

Depending on how you structure your driver’s pay, you could be paying for their days off or they could be missing out on an opportunity to get paid. This could lead to a driver leaving or your business losing a lot of money.

Preventative Fleet Maintenance

So, how do you deal with this?

Using a preventative maintenance plan can help you reduce the likelihood of vehicle breakdowns, broken parts, and general wear and tear. The cost of routine maintenance upfront is significantly less than the cost of driver downtime, vehicle repairs, and even vehicle replacement.

This is the simplest way to reduce long-term costs and keep your fleet productive.

Avoid vehicle downtime at all costs by staying on top of maintenance schedules, training your drivers to practice safe driving behaviors, and keeping your vehicles in the best condition possible.

By keeping up with scheduled checks you can reduce the amount of vehicle downtime significantly. The purpose of annual inspections is to ensure that all aspects of your vehicle are healthy.

Online Fleet Maintenance Program

A fleet maintenance program makes adhering to these schedules easier by sending reminders of routine maintenance checks, inspections, and registration expiration dates. Keep your drivers on the road, your vehicles running smoothly, and your bottom line protected with vehicle maintenance management.

![Episode 50 Thumbnail Erin celebrates building the fleet community with 50 episodes and 11K followers on LinkedIn [Podcast]](https://intellishift.com/wp-content/uploads/2020/08/Downtime-Cost-Chart-1.jpg)