Maximizing the profitability of your fleet is a crucial consideration when scaling your fleet business. Many techniques and tools can help you accomplish this goal.

But, if you’re serious about scaling your business, one of the best things you can do is add a reefer truck (or several) to your fleet. Reefer trucks are more expensive than your traditional trucks but offer many benefits to you and your customers.

So, what is a reefer truck, and how can it help you scale your business? Here’s everything you need to know.

What is a Reefer Truck?

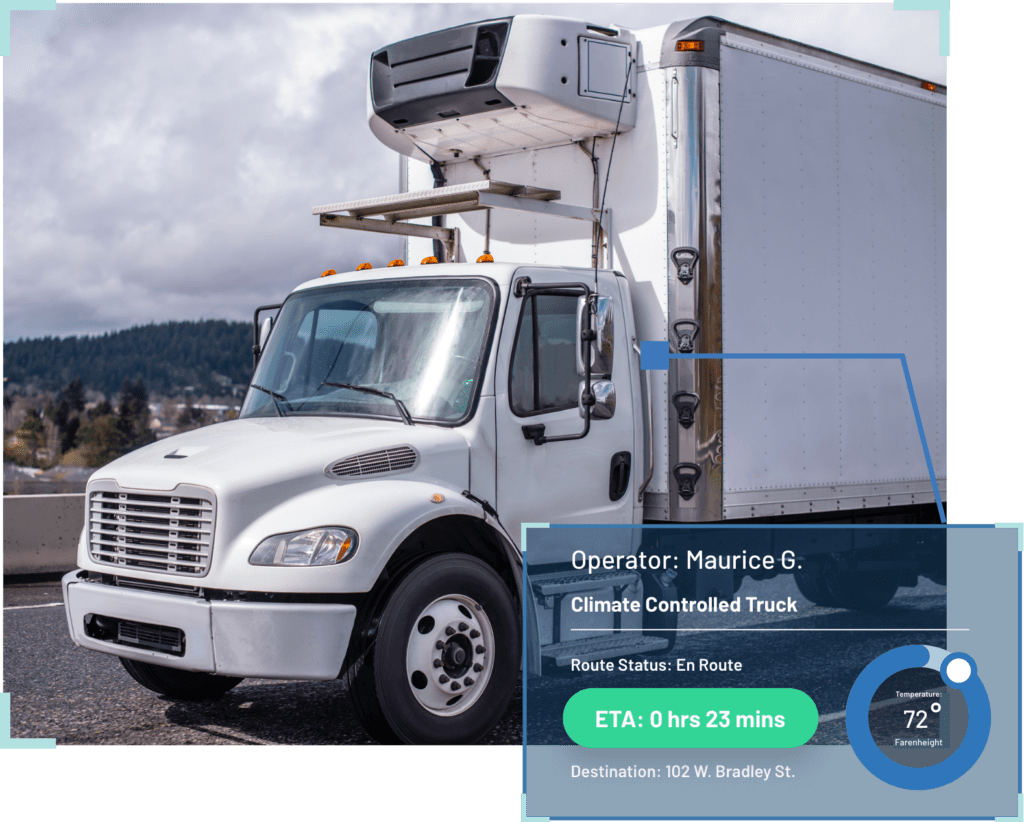

If you’re just getting into the business you may find yourself asking what is a reefer truck? A reefer truck is industry jargon for a semi-truck that hauls a refrigerated trailer rather than a standard trailer.

The term “Reefer truck” is understood throughout the industry by drivers, dispatchers, shipping companies, manufacturers, and retailers, helping everyone understand which type of truck is being discussed. Companies can ship perishable goods widely throughout the country with the help of refrigerated trucks aka “reefers”.

These refrigerated trailers operate much like a regular refrigerator that you would find in your kitchen. They are equipped with a cooling system that allows them to stay cold enough to transport temperature-controlled freight without spoilage, such as refrigerated and frozen foods. The stand-alone cooling system sets it apart from the smaller cooling trucks and vans that are simply well-insulated with proper ventilation.

The closed cooling unit keeps the trailer cold by either diesel-powered generators or cryogenic cooling systems. These systems remove the heat and cycle chilled air throughout the refrigerated trailer to keep the cargo at specific temperature requirements.

Each reefer truck has a reefer unit, an insulated box, an air chute, and an air suspension system. All of these components play a key role in making sure cargo is delivered safely.

How Does a Reefer Unit Work?

A reefer unit works similarly to your refrigerator at home by pushing refrigerant throughout the system. Most reefer units consist of three main parts that work in 3 phases: the compressor, the condenser, and the evaporator.

- Compressor. First, the compressor – which is the main component of the reefer unit – takes gaseous refrigerant and compresses it to create pressure. The compression process turns the refrigerant gas into a hot liquid before sending it to the next part of the unit, the condenser where the heat exchange process begins.

- Condenser. Next, the compressed, hot liquefied gas runs from the compressor through the condenser which contains tubes and fins outside the trailer. The condenser offers enough surface area to cool the refrigerant. The heat exchange process is further aided by a fan that pulls in cool air from outside. The liquid refrigerant begins to cool as the hot liquid runs through the system.

- Evaporator. Finally, as the cool refrigerant runs back into the trailer, it makes its way through the evaporator. The evaporator uses a metering valve to control the level of cooling in the trailer.

As the liquid refrigerant cools, it turns back into a gas and begins absorbing heat again from the system. Air is then pulled back into the system from the trailer, starting the process again.

The same air continuously cycles through the closed cooling unit, keeping the refrigerated trailer cooled to the specified temperature despite temperature fluctuations during loading and unloading.

What Are Reefer Trucks and Reefer Vans Used for?

Reefer trucks and reefer vans are designed to transport temperature-sensitive loads. Most reefers also can have temperatures monitored and maintained using specialized systems. While the first thing that is often associated with reefer vans and trucks is food, they are useful with a wide variety of products.

You can use reefer trucks and vans to ship:

- Perishable Foods (fresh produce, frozen foods, meats, etc.)

- Beverages (dairy, wine, beer, etc.)

- Chewing Gum and Candies

- Hazardous Materials (chemicals, solvents, flammable, acids, etc.)

- Tobacco Products (cigars, cigarettes, etc.)

- Paint

- Flowers

- Candles

- Pharmaceuticals

- Cosmetics

What are the Benefits Associated with Adding a Reefer Unit to Your Fleet?

The many benefits you can realize by adding a reefer truck to your lineup can increase both your fleet’s profitability and productivity. Your company will benefit directly from having reefer trailers in your fleet, but your customers will also benefit as you can now provide additional services and ship climate-controlled cargo.

Earn Extra Profit

As mentioned, reefer trailers can increase profitability. A quick look at the available loads, and you’ll quickly see that cargo that requires refrigeration is offered at a premium.

Not only is reefer freight more valuable, its delicate nature means it is essential that it stays within the required temperature range to prevent spoilage.

You cannot ship these goods without a reefer truck, which often requires a higher upfront cost to add to your fleet. Additionally, these delicate loads require extra steps and precautions to ensure the proper delivery of goods.

The result is that these loads pay more. With each load paying more, your revenues will increase, giving you a reasonable ROI to quickly recoup your costs.

There is Almost Always Work for a Reefer Truck

With dry freight, the availability of well-paying loads is susceptible to influence from economic ebbs and flows. However, given the nature of reefer freight, demand is likely to stay relatively stable. The reality is that everyone will continue to need food and pharmaceuticals even in times of recession.This is seen through the load-to-truck ratios for van loads to reefer loads. Where the van load-to-truck ratio in February 2022 was 7.33, for reefers, it was 13.74. So you’ll continue to find loads to transport with reefer trailers in the mix, even if dry freight slows down.

Fewer Gaps Between Loads

The good news is that because there is always work for a reefer truck, you’re less likely to have gaps between reefer loads. These gaps often result in deadhead miles and detention time–some of the most damaging costs to your bottom line. But, with a dry trailer, there’s a higher chance of incurring these costs.

With the high demand for reefer trucks, adding one to your fleet means you’re almost always likely to find a load to haul back, meaning your truck will rarely travel empty.

Plus, even if you can’t find a reefer load when you need one, you can still pick up a dry load in a pinch. This way, even if your driver has to go a bit out of the way, the shorter the distance you have to run empty, the less impact it will have on your profitability.

Ensure Product Integrity Throughout Delivery

You want to give your customers the best quality service possible as a company. While you can ship dry goods with care, cargo will constantly be subjected to an unstable climate in the trailer (variances in temperature, humidity, etc.).

Because a reefer truck can regulate the temperature and humidity inside the trailer, you can ensure the integrity of the reefer freight. This means goods arriving in good conditions at the correct temperatures, lower chances of spoilage, etc.

What Are the Risks Associated with Adding a Reefer Unit to Your Fleet?

While you can certainly gain many benefits when adding a reefer unit to your fleet, it does come with inherent risks. These risks will be present no matter which model you purchase or how well you care for it. However, there are plenty of ways to minimize the impact these risks have on your bottom line.

The Reefer Truck Doesn’t Stay at the Proper Temperature

One of the biggest concerns is that something goes wrong with the reefer and it doesn’t maintain the proper temperature, putting the entire load at risk of spoilage. This is almost guaranteed to happen at some point–a part will give out, a motor will overheat, etc.

But the best way to deal with it is to have a plan for when the inevitable happens. The best way to tackle this problem is to install tracking equipment that will monitor the temperature of the reefer unit.

These systems will allow both the driver and the company to keep track of the trailer temperature, ensuring that it stays within the acceptable range. Should it show that the temperature is starting to get warm, help can be found or sent right away to get things back on track to keep the cargo safe. Installing a system like this is vital to mitigate your own risk and reassure your customers that their cargo is safe with your company.

You Need to Keep Up with Reefer Maintenance

To keep your reefer from giving up on you, you must keep up with regular maintenance. But as you likely already know, keeping track of scheduled maintenance and knowing when a part is starting to wear out and needs replacing can be a challenge.

The good news is that systems are available to automate your fleet maintenance. These systems will monitor the maintenance of your entire fleet, alerting you when a vehicle needs maintenance, whether it is due to a DTC code, usage, scheduled maintenance, or from a failed inspection.

Preventative maintenance helps keep your fleet on the road. Likewise, keeping each of your vehicles well-maintained can help minimize accidents and reduce downtime.

When it comes to reefers, it is especially important to make sure the refrigeration unit in the trailer stays in peak condition so that temperature control is possible, reducing liability when it comes to spoilage and mishandled refrigerated freight. In other words, by integrating a system that lets you automate your fleet’s maintenance, you can minimize errors, keeping your wheels rolling and customers happy.

Reefers Must be Cleaned Regularly

Adding a reefer to your fleet does require more cleaning than your traditional dry trailer. Regularly cleaning your reefer will help keep the trailer maintained, but it is also necessary to keep the trailer sanitary, given that reefer freight is often frozen food or produce.

In fact, to make sure you continue getting reefer loads, you need to make sure your trailer continuously meets FDA requirements. This means sanitizing the trailer is essential. It’s relatively easy to add these necessary steps to the existing inspection every driver must perform for the DOT.

Just as there are systems to automate your fleet maintenance, systems exist to simplify the DVIR process for reefer trucking. While these reports are traditionally filled in paper form, you can easily integrate an electronic system for drivers to use. You can simply add the cleaning process to the inspection list with these electronic systems.

Using an electronic system will help keep your drivers accountable and ensure that your reefer stays clean and safe for the next load.

You May Need Additional Insurance

You’ll want to get additional insurance for your reefer trucks to protect your company. Reefer loads are sensitive to spoilage, increasing your liability. While commercial auto liability insurance covers bodily injury and property damage liability, additional refrigerated truck insurance can offer protection for cargo liability for refrigerated goods.

If you have an existing fleet and are adding reefers, check with your current provider about bundling reefer truck insurance, which is often more affordable than getting a new policy. This way, you’ll have peace of mind and minimized liability should something go wrong during a run.

How Intellishift Can Help with All Your Reefer Needs

It’s no secret that adding reefers to your fleet can significantly impact your bottom line and increase your company’s profitability. But, the best way to maximize the impact on your business is to integrate automated systems to keep everything running smoothly.

Intellishift is here with a wide range of solutions designed to maximize your profitability and minimize losses in the trucking industry.

Whether it’s transitioning your paper DVIR system to an electronic version, automating your fleet’s maintenance schedule, or monitoring the systems on your new reefer trucks, Intellishift has proven systems that work for fleets of all sizes. Contact our sales team today to discuss how we can help you improve your fleet’s operations.

![Episode 50 Thumbnail Erin celebrates building the fleet community with 50 episodes and 11K followers on LinkedIn [Podcast]](https://intellishift.com/wp-content/uploads/2022/08/iStock-503084489.jpg)